-

ZHENFU-Healthcare Air Filtration

Views: 0 Author: Site Editor Publish Time: 2023-10-24 Origin: Site

Where is a breathing filter used?

Even in a hospitalized environment, it is challenging to guarantee sterilization of equipment for each surgical patient since every day several scheduled surgeries as well as emergency procedures are completed in a single operating room. Sterilization of the apparatus requires special equipment and can take a long time meaning expensive equipment has too much downtime. Using a single use, disposable bacterial/viral filter during the implementation of anaesthesia will severely reduce cross infection between the patient and machine. As the filters are single use per patient the equipment does not need to be sterilized each time enabling machines for surgery to be used more quickly and efficiently.

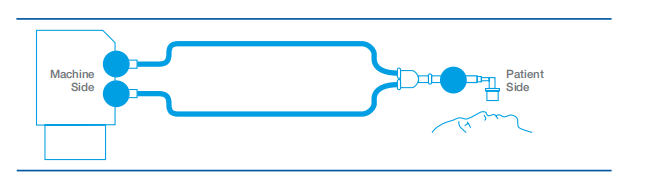

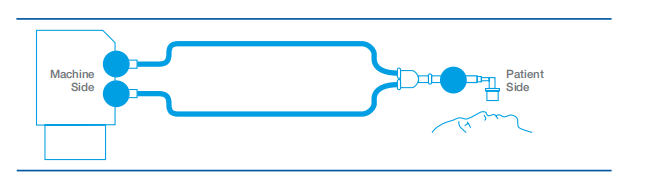

Filter Location in the System

The filter can be positioned at the patient Y piece, in the Expiratory or Inspiratory limb of the breathing circuit to reduce the risk of a patient becoming infected via the apparatus or closest to the patient to reduce risk of the patient contaminating the machine.

Why a filter is used

The primary purpose of breathing filters placed between the patient and the respiratory circuit is prevention of cross infection between the patient and apparatus when performing endotracheal anaesthesia or mechanical lung ventilation.

These procedures require that the upper airway be bypassed during respiration. The purpose of the upper airway is to remove particulates from the air to deactivate bacteria and viruses by means of biologically active substances having bactericidal and viricidal properties. These are secreted by the mucous membrane, and also to warm inspired air to 35°C-36°C and to humidify it to a relative humidity of 98%-100%

Problems that patients encounter

In addition to the purification of the breathing mixture the upper airways but also provides humidification and warming.

In mechanical lung ventilation, the breathing mixture enters the trachea, bypassing the upper airways.

The lack of humidification and warming of the breathing mixture can result in the following complications:

• Hypothermia causing the body to drop below a normal temperature.

• Dehydration, which can cause hypotension.

• Inhalation of contamination and cross infection.

• The mucous membrane swells which disrupts the movement of the mucous in the direction of the pharyngonasal cavity.

• Necrosis of the epithelium and mucous membrane which deprives the lungs of their protective function, leading to lung collapse, infection, pneumonia and other illnesses.

Filters Limit the Risks

Transmission of infection during endotracheal anaesthesia and prolonged lung ventilation can be prevented by placing a disposable filtering device between the patient and the respiratory circuit. The breathing filter, can also be given the properties of a heat and moisture exchanger to reduce the risk of dehydration and excessive drop in body temperature. As well as providing a barrier to particulate matter entering the patient airways, using breathing filters significantly increases the material resources of the anaesthesia and respiratory equipment.

Type of Filtration Devices

The type of breathing filter and also where it is placed depends on the type of illness, and the physiological characteristics of the patient.

Bacterial / Viral Filter – Removes particles only.

HME – Heat Moisture Exchanger – This filter type contains a foam which retains and returns heat and moisture to the patient. However this filter type does not remove particles.

HMEF – Heat Moisture Exchanger + Filter – Like the HME, the HMEF retains and returns heat and moisture but also contains either a pleated or electrostatic filter media that will remove particles.

How Filters Works

Pleat filters and electrostatic filters both work in different ways.

The positive and negative charge on filter fibres is generated during the manufacturing process and enhances the filter’s ability to attract particulate matter.

Pleat filters work purely on mechanical filtration and direct interception. Particles which are larger than the pore size of the filter media are unable to pass through and as the filter collects particles the matrix becomes tighter therefore increasing the efficiency.

FILTRATION MEDIA COMPARISON

The hospital environment is increasingly a potential source of infection and with the increased incidence of infectious diseases the possibility of cross contamination due to the reuse of equipment or the sharing of equipment is a real risk. ZHENFU is able to offer different types of filtration solutions for the protection of patients and equipment in the Medical field.

Electrostatic Media

Efficiency: achieved through electrical charge in the media (created through friction during manufacture).

Consistency: the electrical charge will dissipate when exposed to moisture, leaving a more open matrix.

Inconsistency arises when the charge has dissipated but insufficient particulates have been collected between the fibres to aid mechanical filtration.

Protection: electrostatic media cannot repel blood or fluids. If the filter becomes wet its function deteriorates, and if occluded by fluid the fluid can penetrate and enter the device.

ZHENFU electrostatic filters utilize a unique patented ‘triboelectrical charge exchange’ between a specially developed blend of polymers to induce a highly stable electrical charge on every individual fibre in the media to more easily trap small particles. The advantages of this type of filter are: efficiencies up to 99.9999%, low manufacturing costs and ease of construction.

Pleated Hydrophobic Media

Efficiency: achieved by using high-grade paper which is then pleated to increase the filtration area.

Consistency: maintained throughout filter use as the fibre matrix is much closer with performance related to the volume of media to achieve efficiency, rather than an electrical charge to boost it. There is no risk of inconsistency arising as with electrostatic filters.

Protection: a special treatment of the media enables it to repel blood and fluids thereby preventing it from passing into the system and risking contamination, or the filter losing efficiency at being able to filter the air.

ZHENFU mechanical pleated filters carry hydrophobic properties which provide a complete barrier to viral pathogens under normal clinical conditions. Efficiencies up to 99.99999% are available among ZHENFU range of mechanical pleated filters. The advantage of an ability to cope with most particle sizes, high efficiency over long periods, increased efficiency over time, and the highest possible performance (99.99999% on 24 Hour Test) need to be balanced against the higher cost of production.

Bacterial and Viral Testing

This is normally performed at an independent test facility which develops specific protocols to simulate the types of challenges that a filter may see in the clinical setting. A challenge particle is chosen to simulate the size of the commonly occurring bacteria and viruses. Generally these tests are not conducted using a “live” virus due to the cost and safety issues. ZHENFU has appointed Nelson Laboratories, Utah, USA as their independent test facility. Their bacterial test protocol uses Staphylococcus Aureus as a challenge organism which has an approximate size 0.6 mm and the viral test uses an X174 Bacteriophage which has a size of 0.027 μm. It is worth noting that the HIV virus is 0.08 μm and Hepatitis C is 0.02 μm so the test protocol does offer a clinically relevant reflection of their performance.

Penetration Test

A standard BS EN ISO 23328 (Breathing System Filters for Anesthetic and Respiratory use. Part 1 Salt Test method to assess filtration performance) has been developed as a method of benchmarking the performance of one filter against another. The test requires the filter to be challenged by a 0.3 µm

Sodium Chloride particle at a flow rate of 30 Liters per minute. The level of penetration is measured and the resulting efficiency reported as a percentage.

i.e.if a filter has penetration rate of 0.5% the filters performance will be recorded as 99.5% efficient. This test allows a direct comparison of how individual filters perform. Under this system a filter must be more than 99.97% efficient to classified as a HEPA filter. Most of the ZHENFU pleated filters are individually tested during manufacture to confirm that they are all HEPA performance.

The quality of connections of the filter housing is vital to ensure a safe secure fitting within the patients breathing system during clinical use. All of the 15 mm & 22 mm tapered connections are tested and comply with ISO 5356 for maximum patient safety. It is now common clinical practice to continually measure the gas that the patient is breathing in and expiring during the procedure. The filters have been designed to comply with ISO standards to ensure a safe secure fit to monitoring devices. In addition the “Cap & Strap” design is an integral part of the molding minimizing the possibility of it becoming detached and inadvertently occluding the airway, improving patient safety. The products are all designed to meet the clinical requirements from the smallest baby to the largest adult, with a focus upon minimal resistance, minimum weight and product dead space, combined with the maximum possible product efficiency.

Clinicians may choose a combined product which offers both filtration and humidification (HMEF) to the respiratory gases. This helps alleviate any symptoms associated with breathing cold dry medical gases for a prolonged period of time. The performance of all HME products is verified by independent testing of the product against ISO 9360.

Tidal Volume: (VT) The volume of gas inhaled and exhaled by the patient during one respiratory cycle. The average for a 70 Kg adult is 500 ml.

Minute Volume: (MV) The quantity of gas exhaled from the lungs per minute; i.e. the tidal volume multiplied by respiratory rate. An average 70Kg Adult with a respiratory rate of 12 breaths per minute (500 ml x 12) would have a minute volume of 6 liters.

Dead Space: There are two types.

1) Anatomical Dead Space is the volume of the patient airways of the nose, mouth, and trachea down to the level of the alveoli, representing the portion of inspired gas unavailable for exchange of gases with pulmonary capillary blood. The average anatomical dead space of a 70 Kg adult is 150 ml.

2) Breathing System Dead Space is the volume of any breathing system components which is adding to the portion of the inspired gas that is unavailable for exchange of gases with pulmonary capillary blood.

Resistance: This is an expression of the amount of effort that is required to make an inspiratory or an expiratory breath.

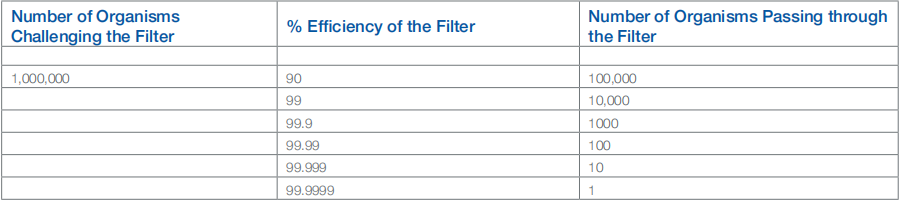

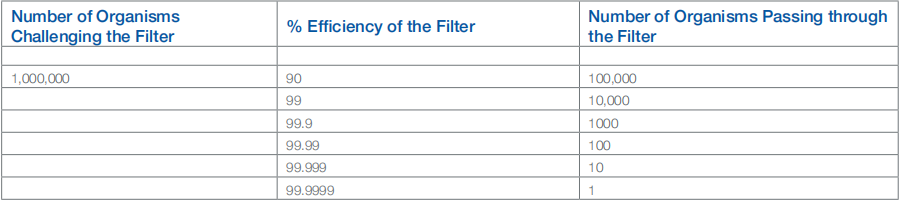

Efficiency: This will be the level of filtration protection or function that the device can deliver. The efficiency of the filter is normally expressed as a reflection as the number of micro organisms that pass through the filter media when it is challenged. This filter is then described as being X% efficient. The X% is an expression of the number of organisms penetrating the filter when challenged by an aerosol containing 1,000,000 micro organisms.

The table below explains the relevance of the X% on performance and level of protection in the clinical environment.

HME: Heat Moisture Exchanger. These devices allow heat and moisture to be captured from expired gases and then returned to the patient in the inspired gases. This is established by testing against ISO 9360 -1 &2 2000 “Anesthetic & Respiratory Equipment, HME’s for humidifying respired gases in humans”.

Capnography: This is the measurement and graphic display of CO2 levels in the airways, which can be performed by infrared spectroscopy. A small sample of inspired and expired gases is taken via the gas sampling port on the filter. Capnography assists in the management of the patient by providing continuous and non invasive monitoring of ventilation in critically ill and anaesthetized patients. It allows early detection of clinically significant changes in respiratory status by displaying changes in the amount of CO2 and abnormal CO2 waveforms.

ISO: International Standards Organization is a group which has developed test and performance standards to introduce normalized standards of global practice and help improve patient safety.

ZHENFU's Filters

ZHENFU offers a range of filters for use within Anesthesia, Respiratory, Critical Care and Surgical clinical areas. These filters are used with patients whose upper airways are being bypassed by an artificial tracheal airway removing the patients natural ability to filter inspired air or receiving artificial ventilatory support where a gas is being introduced into a body cavity as during Laparoscopic surgery or to protect equipment, staff and the environment from potential cross contamination. The hospital environment is increasingly a potential source of infection and with the increase incidence of infectious diseases the possibility of cross contamination due to the reuse of equipment or the sharing of equipment is a real risk.

Feature

Benefit

Low dead space

Minimizes possibility and dangers associated with re-breathing Carbon Dioxide

Light weight

Reduces any pull on patients tracheal connection

Transparent

Allows easy visualization of any potential blockage

ISO Tapered Connections

Guarantees safe, secure connection to the breathing system

ISO Gas sampling port

Easy, safe monitoring of expired gases

Complete Product Range

Meets all clinical requirements from Neonatal to Adults. Offers protection for all types of medical equipment from airborne and liquid cross contamination.

Proven performance

Offers high efficiency protection against bacterial and viral contamination. Independently tested and validated. Efficiencies up to 99.99999%

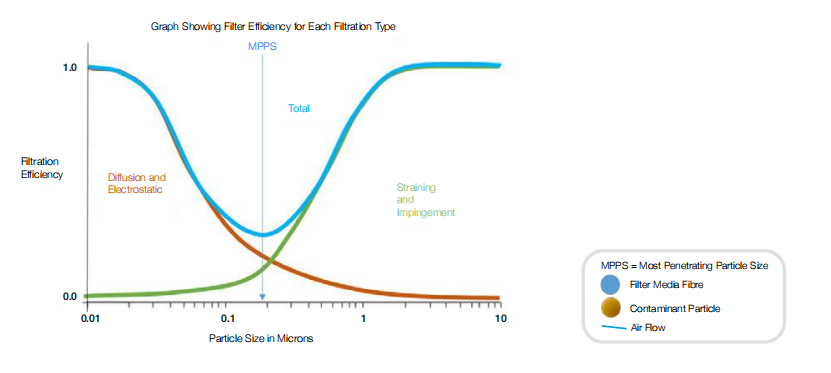

THE THEORY OF FILTRATION

Particulate matter is captured within a filter by 4 main methods:

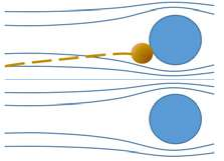

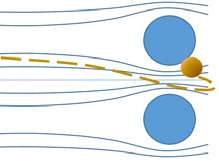

Straining - The physical capture of a particle by the fibres or holes in a media preventing it passing due to their relative size.

Straining - The physical capture of a particle by the fibres or holes in a media preventing it passing due to their relative size.

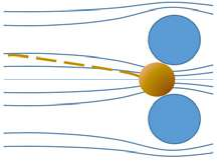

Impingement - The particle physically hits and sticks to the fibre.

Impingement - The particle physically hits and sticks to the fibre.

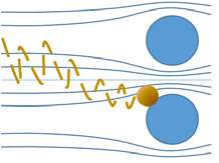

Diffusion - Brownian motion causes the particle to move in irregular patterns increasing it chance of making contact with and adhering to the filter fibres.

Diffusion - Brownian motion causes the particle to move in irregular patterns increasing it chance of making contact with and adhering to the filter fibres.

Electrostatic - The particulate is attracted to the media though an electrostatic charge. This is generally only in synthetic media and very often this electrostatic charge diminishes with time and/or humidity.

Electrostatic - The particulate is attracted to the media though an electrostatic charge. This is generally only in synthetic media and very often this electrostatic charge diminishes with time and/or humidity.MPPS - The most penetrating particle size varies between different media, contaminants and according to air flow.

Generally as air flow increases, efficiency decreases.

Related Products

content is empty!

Related News

content is empty!

CONTACT US

NO.176, Gaoxin 5th Road, High-tech Industrial Park, Rizhao City276800, Shandong Province, China +86-13396234532 +86-13396234532Copyright © 2023 ZhenFu Group All Rights Reserved. Technology By leadong.com | Sitemap | Privacy Policy

Straining - The physical capture of a particle by the fibres or holes in a media preventing it passing due to their relative size.

Straining - The physical capture of a particle by the fibres or holes in a media preventing it passing due to their relative size.