-

How to Properly Install and Maintain Insufflation Filters and Tubing?

Views: 0 Author: Site Editor Publish Time: 2024-09-16 Origin: Site

Insufflation filters and tubing are essential components in various medical and laboratory applications, ensuring the safe and efficient delivery of gases and aerosols. Proper installation and maintenance of these components are crucial for optimal performance, preventing contamination, and ensuring the safety of both the user and the environment. In this article, we will explore the key steps for installing and maintaining insufflation filters and tubing, as well as the importance of these practices in maintaining the integrity and reliability of your equipment.

Understanding Insufflation Filters and Tubing

Insufflation filters and tubing are critical components used in various medical and laboratory applications, including respiratory therapy, anesthesia delivery, and aerosolized medication administration. These components ensure the safe and efficient delivery of gases and aerosols while preventing contamination and maintaining the integrity of the equipment.

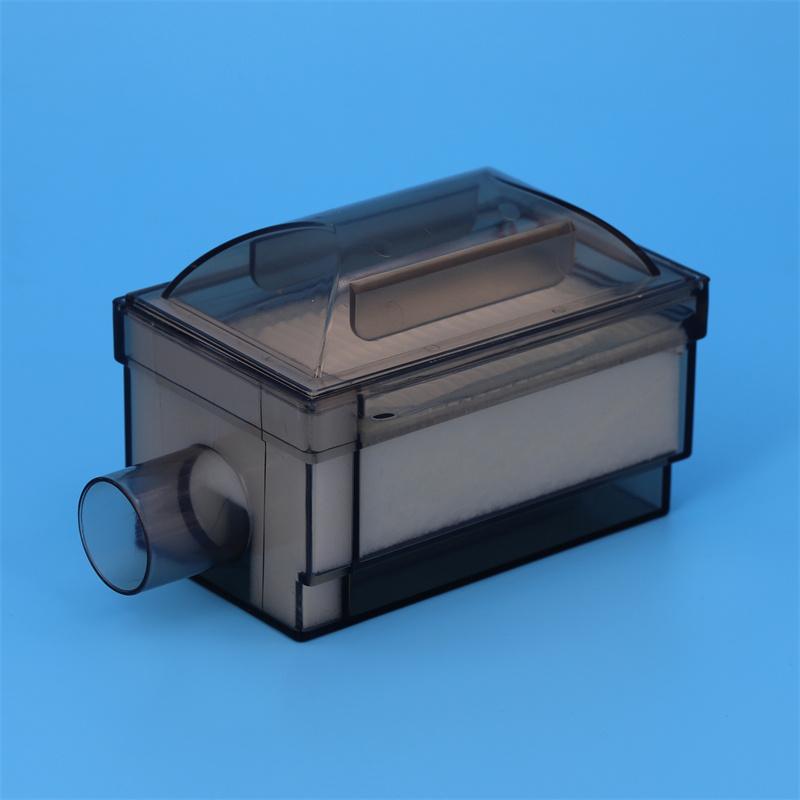

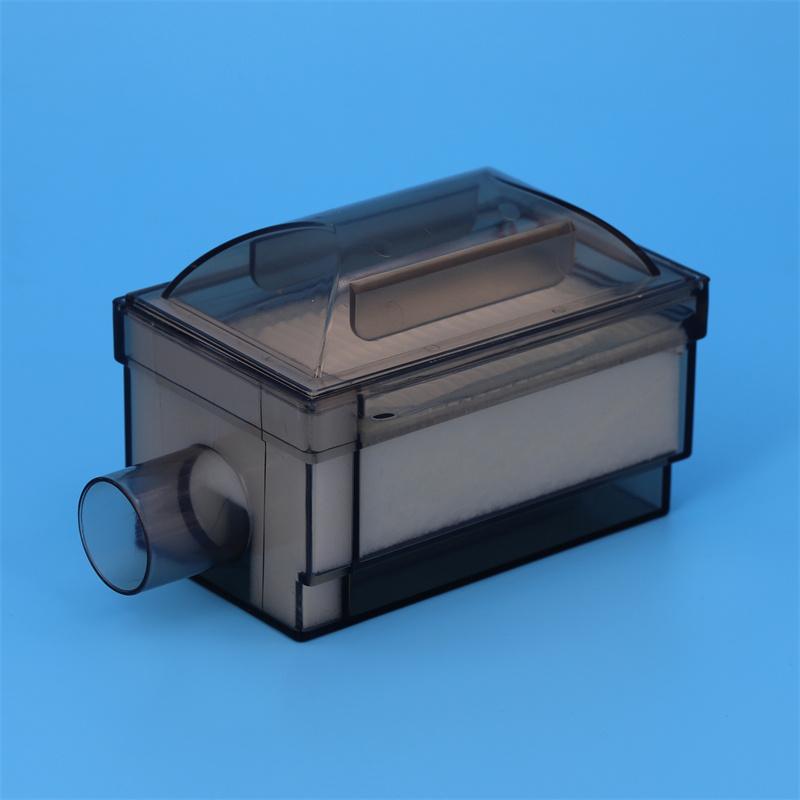

Insufflation filters, also known as bacterial/viral filters (BVFs), are designed to trap and filter out harmful particles, including bacteria, viruses, and other contaminants, from the gases or aerosols being delivered to the patient or the environment. These filters are typically made from hydrophobic materials, such as polytetrafluoroethylene (PTFE), and are designed to provide a high level of filtration efficiency while maintaining low resistance to airflow.

Insufflation tubing, on the other hand, is used to transport the filtered gases or aerosols from the source (e.g., a nebulizer, ventilator, or anesthesia machine) to the patient or the environment. This tubing is typically made from flexible, biocompatible materials, such as silicone or PVC, and is designed to provide a secure and leak-free connection between the filter and the delivery device.

Proper installation and maintenance of insufflation filters and tubing are crucial for ensuring optimal performance, preventing contamination, and ensuring the safety of both the user and the environment. Failure to properly install or maintain these components can result in compromised filtration efficiency, leaks, and potential exposure to harmful particles or contaminants.

Installation Guidelines for Insufflation Filters and Tubing

Proper installation of insufflation filters and tubing is essential for ensuring optimal performance, preventing contamination, and ensuring the safety of both the user and the environment. The following guidelines should be followed when installing insufflation filters and tubing:

1.Choose the correct filter and tubing: Ensure that the selected filter and tubing are compatible with the equipment being used and meet the specific requirements of the application. Consider factors such as filter efficiency, tubing diameter, and material compatibility when making your selection.

2.Prepare the equipment: Before installing the filter and tubing, ensure that the equipment is clean and free of any contaminants. Remove any old or used filters and tubing, and clean the connection points on the equipment using an appropriate disinfectant or cleaning solution.

3.Install the filter: If the filter is not pre-installed in the tubing, carefully attach the filter to one end of the tubing, ensuring that the arrow or indicator on the filter is pointing towards the patient or the environment. Ensure that the filter is securely attached and that there are no gaps or leaks at the connection point.

4.Attach the tubing: Connect the other end of the tubing to the appropriate delivery device, such as a nebulizer, ventilator, or anesthesia machine. Ensure that the connection is secure and that there are no gaps or leaks at the connection point.

5.Test the system: Before using the equipment, test the system to ensure that the filter and tubing are functioning properly and that there are no leaks or issues. Check the connections, and ensure that the filter is properly seated and functioning as intended.

Maintenance Tips for Insufflation Filters and Tubing

Proper maintenance of insufflation filters and tubing is essential for ensuring optimal performance, preventing contamination, and ensuring the safety of both the user and the environment. The following maintenance tips should be followed to keep your insufflation filters and tubing in good condition:

1.Regularly inspect filters and tubing: Periodically check the filters and tubing for signs of wear, damage, or contamination. Look for cracks, tears, discoloration, or other signs of deterioration. If any issues are detected, replace the affected components immediately.

2.Clean and disinfect: Regularly clean and disinfect the filters and tubing to remove any contaminants and prevent the buildup of harmful particles. Use appropriate cleaning and disinfecting solutions that are compatible with the materials of the filters and tubing.

3.Replace filters as needed: Insufflation filters have a limited lifespan and will need to be replaced periodically, depending on the frequency of use and the specific application. Follow the manufacturer’s recommendations for filter replacement intervals and replace the filters as needed to ensure optimal performance.

4.Store filters and tubing properly: When not in use, store the filters and tubing in a clean and dry environment to prevent contamination and damage. Use appropriate storage containers or bags to protect the components from dust, moisture, and other potential contaminants.

5.Train personnel on proper handling and maintenance: Ensure that all personnel who handle and maintain insufflation filters and tubing are properly trained on the correct procedures and best practices. This includes training on proper cleaning and disinfecting techniques, as well as the proper use and handling of the components.

Conclusion

Proper installation and maintenance of insufflation filters and tubing are crucial for ensuring optimal performance, preventing contamination, and ensuring the safety of both the user and the environment. By following the guidelines and maintenance tips outlined in this article, you can ensure that your insufflation filters and tubing remain in good condition and continue to provide reliable and effective performance. Regular inspection, cleaning, and replacement of filters and tubing, as well as proper storage and handling, are essential for maintaining the integrity and reliability of your equipment. By taking the time to properly install and maintain these components, you can ensure that your equipment continues to function effectively and safely for years to come.

Related Products

content is empty!

Related News

content is empty!

CONTACT US

NO.176, Gaoxin 5th Road, High-tech Industrial Park, Rizhao City276800, Shandong Province, China +86-13396234532 +86-13396234532Copyright © 2023 ZhenFu Group All Rights Reserved. Technology By leadong.com | Sitemap | Privacy Policy